| Product Uses | Product Features | Demonstration Videos |

| Product Test Results | Product Comparison |

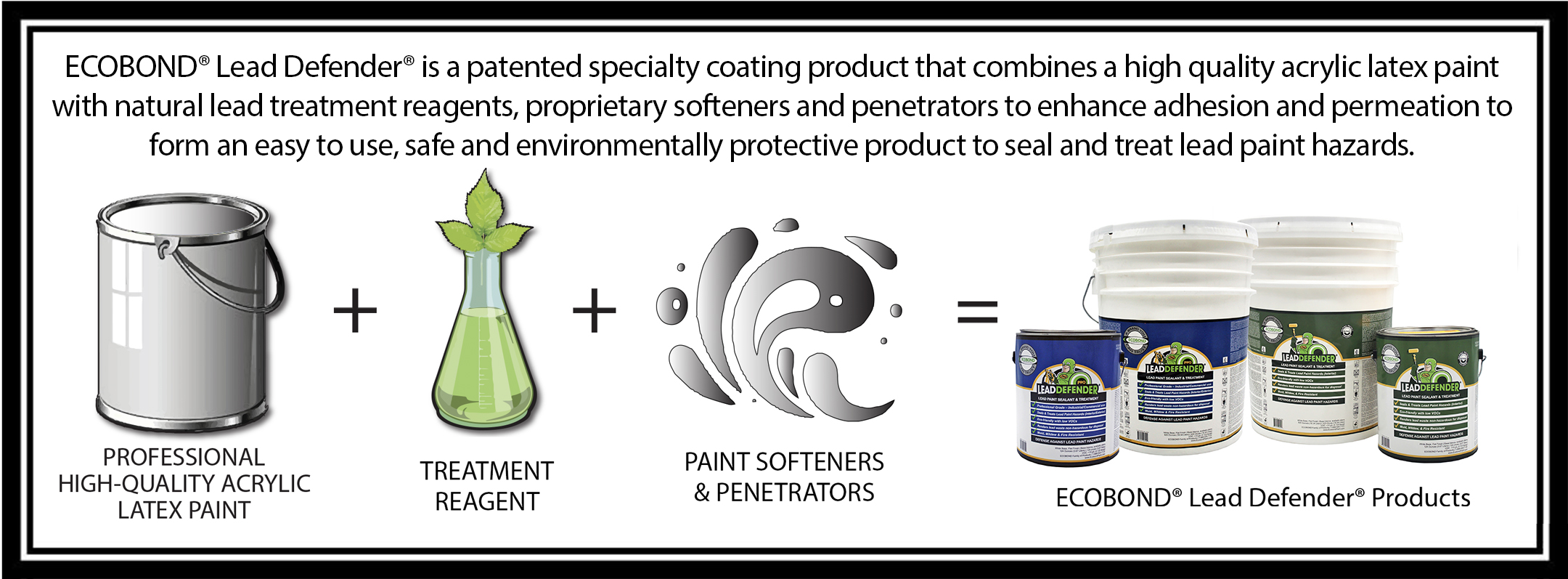

LeadDefender® is a specialty paint product formulated to seal and treat the hazards of lead based paint. It is so versatile it is easily used by homeowners (DIY), residential, commercial and industrial contractors, and is specified by numerous government agencies.

Uses of LeadDefender®

Not only is LeadDefender® preferred by a wide variety of users, it is also a multi-purpose product applicable for a wide range of lead based paint projects such as:

Remodeling, Renovation and Painting - RRP(Residential and Commercial Structures)

- Interior primer and tintable topcoat (walls, doors, cabinets, and trim)

- Exterior primer (siding, trim, and exterior structures)

Renovation, Maintenance and Demolition(Industrial Buildings, Bridges, Tanks, etc.)

- Prevent the spread of lead dust, treat lead dust

- Treat lead in lead paint for non-hazardous disposal

Prior to Lead Paint Component Removal

- Use LeadDefender® to seal and treat lead dust and lead paint prior to component removal. Through proper application of LeadDefender®, removed and collected solid waste will typically provide eco-friendly disposal as non-hazardous for lead. As disposal and sampling requirements vary by state and locality, check with your local agencies for additional requirements.

Interim Control

- LeadDefender® is allowed for use in all 50 states as Lead Paint Interim Control (42 USC 63A 4851b(13)), check your local requirements.

Lead Dust and Lead Paint Treatment

- LeadDefender® is specially formulated to address lead dust and lead paint issues. Its patented formula chemically converts lead in lead paint and lead dust to provide stabilization that virtually eliminates leaching of lead to the environment allowing for lower cost, non-hazardous, eco-friendly waste disposal; reduces lead hazards up to 95%; and improves worker/occupant safety.

Product Features

| Feature | Benefit |

| Patented LeadDefender® lead treatment technology | Seals and treats lead dust and lead paint to help |

| Reduces airborne lead dust up to 99% | |

| Reduces lead hazards up to 95% (EPA method 1311) | |

| 100% acrylic latex paint product | Interior primer, sealant and topcoat |

| Tintable (add up to 6-8 oz liquid colorant) | |

| Easy to apply (sprayer, roller or brush) | |

| Easy clean-up (use water) | |

| Low VOC's (Volatile Organic Compounds) (<50g/L) | |

| Contains paint penetrators and softeners | Formulated for maximum adherence |

| Expansive coverage (~300 sf/gal) | Low cost (<25¢ /sf) |

| Additional Features | Fire resistant (ASTM E84-11A) |

| Mold/mildew resistant (ASTM D5590-00 mod) | |

Reduces relative lead bioavailability up to 85% | |

| Pre-textured |

Click here to download Product Data Sheet

LeadDefender® LBP Test Results

Typical Industrial Lead Hazard Treatment Project Sampling Results

- This lead hazard project included both lead dust and lead contamination in paint and in a variety of building materials including wood, cinderblock sheet rock, concrete and ceramic tile. Sampling confirmed lead levels up to 100,000 ppm or 10% by weight, which is considered a substantial risk.

| Sample ID | Type of Material | Wipe Sample Before Treatment ug/ft2 | Wipe Sample After Treatment ug/ft2 | TCLP Sample After Treatment (mg/L) |

| W-1 | Wood | 4,980 | <500* | 0.60 |

| W-2 | Cinderblock | 184,000 | 336 | Non-Detect |

| W-3 | Sheet Rock | 4,680 | 306 | 0.26 |

| W-4 | Concrete | 1,690 | 251 | Non-Detect |

| W-5 | Ceramic Tile | 2,470 | 202 | Non-Detect |

* Two coats

LeadDefender® has been Successfully Tested on Over 1,000 Samples

- This table represents a small, randomly selected historical sample subset and demonstrates LeadDefender®'s robust ability to successfully treat lead to below US EPA standard of 5.0 mg/L TCLP Pb

| Sample ID | Pre-LeadDefender® Treatment | Post-LeadDefender® Treatment (mg/L) | % Reduction |

| A | 77.1 | 2.34 | 96.66 |

| B | 68.8 | 0.56 | 99.09 |

| C | 116 | 0.90 | 99.22 |

| D | 85.6 | 1.30 | 98.41 |

| E | 77.15 | 0.50 | 99.35 |

| F | 56.45 | 0.25 | 99.56 |

| G | 87.2 | 1.20 | 98.62 |

| H | 65.58 | 0.33 | 99.50 |

| I | 64.9 | 1.00 | 98.46 |

| J | 223.5 | 0.30 | 99.87 |

| K | 143.77 | 1.33 | 99.08 |

| L | 80.4 | 1.33 | 98.35 |

| M | 67.73 | 0.67 | 99.01 |

| N | 61.16 | 0.33 | 99.46 |

| O | 51.74 | 0.83 | 98.40 |

| P | 85.33 | 0.83 | 99.03 |

| Q | 51.74 | 0.67 | 98.71 |

| R | 68.41 | 0.67 | 99.02 |

| S | 26.82 | 0.83 | 96.91 |

| T | 83.66 | 0.56 | 99.33 |

LeadDefender® Treatment to Reduce Relative Lead Bioavailability

- Independent test results following US EPA test procedures 9200.1-86 demonstrate LeadDefender®'s unique patented capacity to reduce the potential for relative lead bioavailability (lead absorbed into the bloodtream) by up to 85%, providing a significant potential to reduce childhood lead poisoning and enhance household/worker safety.

| Untreated | Treated with LeadDefender® | Total Reduction** (EPA 9200.1-86) | |||

| Sample ID | IVBA Pb (mg/L) | IVBA % | IVBA Pb (mg/L) | IVBA % | % Reduction |

| LBP1-22-6* | 1,040 | 73.20 | 320 | 23.9 | 68 |

| LBP1-22-9* | 338 | 25.60 | 133 | 9.10 | 64 |

| L98390-3* | 113 | 11.10 | 23.1 | 2.90 | 74 |

| L98390-2 | 113 | 11.00 | 31.5 | 3.70 | 67 |

* One coat of LeadDefender®, 8-12 mil wet

** At non-fasting pH 2.2

Cost Comparison

- According to the US EPA, lead based paint removal costs are estimated at $8 - $15 per square foot; a house of 1,200 - 2,000 sf could cost as much as $9,600 - $30,000.

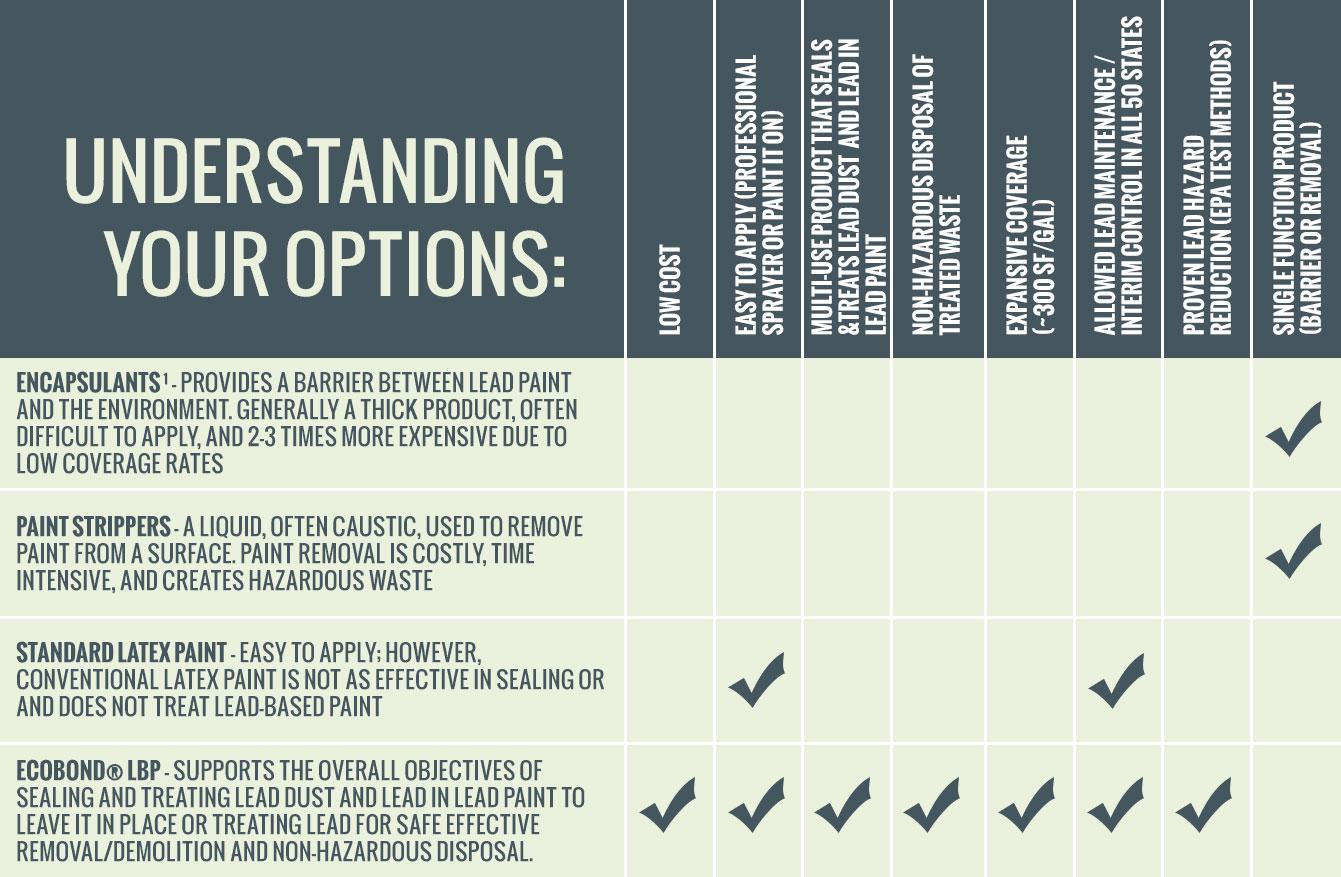

- There are several options for dealing with lead based paint during renovation, repair and painting (RRP), remediation and demolition, lead paint stabilization, and prior to removal; the challenge is findng the best solution - one that provides a safer work environment, is cost-effective, easy to use, and eco-friendly.

The following table provides a summary of key considerations for selecting your lead based paint mitigation product: